Fukushima’s Knit Cultivates the Russian Market: JKB Project Committee

The city of Date in Fukushima Prefecture is the center of world-class skills in knit fabric manufacturing. Knitted fabrics are made by weaving loop-shaped threads and in the 60s and 70s, up to 1000 manufacturers lined the streets of Date, filling the air with the sounds of the loom. Today, since the emergence of other Asian nations, the city’s knit fabric industry has followed a course of decline. However, under the initiative of the Japan Knit Brand (JKB) Project Committee, a movement to regenerate it through JAPAN Brand is suddenly gaining momentum. We went to find out more about the Committee’s unique approach in exploring ways of survival for the local industry.

Interview by Takafumi Suzuki

Translated by Natsumi Yamane

We heard that here in Date, Fukushima Prefecture, you are adopting a rather different approach to the operations of JAPAN Project compared to other participants.

What we would like to introduce to the world is our local industry’s expertise in knit fabric that dates back to around 1950. But not all of the members of its promotion committee are manufacturers of knit products and in fact, the project is promoted mainly by people outside the knit industry. After all, experts know best and you can’t easily ask knit manufacturers who have been dedicating themselves to making things to take care of trade transactions, event planning, advertising and so on. That’s our opinion, you see. So we decided to comprise the committee with human resources with greater experience in the respective areas.

But with such committee members, don’t you experience any difficulties in product development?

What we are attempting to do now is all about our knit manufacturing capabilities rather than making things with traditional skills or marketing new products. Here in Date, we have solid expertise and equipments for knit manufacturing that we have accumulated over many decades and we felt that what we should market is our high level of skills that we already have and produce high quality items rather than the finished new products that are ready to go on the shelves. For instance, our pattern makers here have the ability to convert every single line into three-dimensions from only the simplest design sketches. They transformed rough sketches faxed by a Russian designer into tridimensional knit materials in a small amount of time so the designer was quite surprised. (laughs)

I heard that the method of knit manufacturing handed down here in Date is called Yanagawa Knit but what are the features of the local knit manufacturing?

We have exceptional technologies for knit manufacturing in this city. That you can also tell from the fact that we have the biggest share in luxury ladies’ knitwear in Japan. Many factories converge on this city and you can find equipments that integrate cutting-edge computers as well as craftsmen who still have the high skills to use hand operated knitting machines. In other words, we have all the basis we need for manufacturing high quality knit products and all we need to do is to utilize it.

What is the history behind such fertile soil for knit manufacturing?

In the old days, the city was dubbed the ‘Silk City’ Yanagawa and it was a thriving center of silk production. However, since synthetic fabrics became available from around 1950s, manual silk cultivation struggled to get by as an industry. So it turned its eyes to the textile industry, which caught the waves of the high economic growth and in the 60s and 70s, it developed itself into a major local industry. However, as you know, Yanagawa’s knit began to lose its momentum with the emergence of Chinese and Korean knit products and eventually reached its present situation.

Why are you focusing on the Russian market now?

We chose Russia as the result of a careful consideration on where we should create the market. Not Italy, France or U.K. but Russia, because we thought Russia is friendly toward Japan and that the country would show greater affinity toward the delicacy and coolness of Japanese products. Moreover, Russia is a resources power so they have a history of importing all sorts of items. You might find it surprising but they even have a history of importing knit products from Turkey and Belarus. We Japanese aren’t yet aware of the appeals of Russia. By that we mean not only their cultural aspects but they are also attractive in terms of their market. Russians are looking for quality materials and skills and they show much respect to such distinguished products with added values as we produce in Japan. That’s another reason we felt their market may be open to Japanese products.

Did you actually get any feedback?

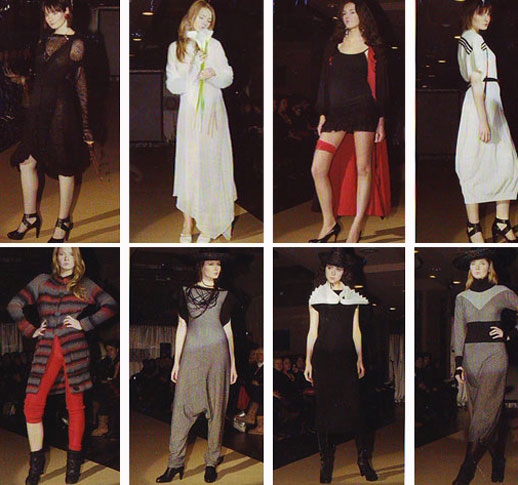

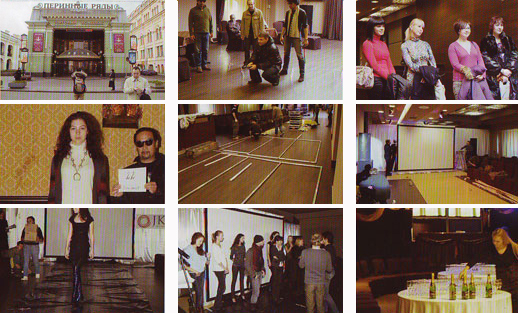

In 2008, we organized two fashion shows, one in January in the capital city of Moscow and another one in November at the Premium Hall in Russia’s economic center, St. Petersburg. The latter show was particularly successful, in which 6 companies led by knit manufacturers from Date participated with 6 Russian models introducing 40 designs by a Russian designer. Around 300 industry insiders and members of the entertainment industry packed the hall to catch a glimpse of this show. The Russian designer who used our knit manufacturing skills in his designs seemed extremely pleased when he looked at the finished products, although he didn’t seem to be expecting that much at first…(laughs) With this attempt, we were able to show that the city of Date has high skills to respond to orders of any kind of knit products.

What do you think is necessary to cultivate the Russian market?

What we consider most important now is building human relationships. However fine products we produce or high skills we have, it’s difficult to do business if human relationships aren’t built properly. Products and skills reach customers only through people-to-people exchanges and trustworthy partners and that goes for both Japan and Russia. That’s why we are concentrating our efforts on exchanges with people from the Russian industry.

From what we have heard so far, the project seems to be going really well. What’s the secret of this success?

I suppose it’s important to ask modestly and honestly, without any wheeling or dealing. Actually, maneuvering might be a big no-no.

What do you have in your mind for the future?

Right now, we are hoping to realize exhibitions, fashion shows and business negotiations at the Russian Embassy in Azabu in Tokyo. And it would be great if we can receive orders for knit manufacturing too.

A Word from a Regional Project Participant

CEO, Daisan Co. Ltd.

There is a difference between the know-how for making things and the know-how for creating things. In our project, we intend to market our know-how for making things or to put it simply, our manufacturing capability, because such know-how for creating things as product planning and design can be managed by anyone from any country. With the human resources and equipments accumulated here in Yanagawa, we can manufacture just about any kind of knit product. What we would like to promote to our target market in Russia is this high value-added manufacturing capabilities. Now is not the kind of times when you can sell any product you produce and in the sense that we are targeting a limited customer base and niche industries, marketing products with added value requires a competitive edge. In the past, we Japanese built factories in China and Korea to mass-produce products at low cost and placed orders with them to pursue only the immediate profit. It’s not that China and Korea originally had knit manufacturing capabilities and advanced into this market. Now, we have to bear that burden. So in our future JKB Project, we would like to consider that point carefully, look ahead to the future of the production centers and avoid risks while creating a recycling-oriented system of making things. And it would be great if we can rejuvenate the knit fabric industry of Date in that process.

Japan Brand

Japan Brand