Natural Fibers with a Heavenly Aroma: Soejima

Anyone who has spent time in a Japanese home will remember the distinctive straw-like aroma of tatami mats. Even in this age of concrete high-rises, many homes and apartments still have at least one room which uses this traditional floor covering. The grass that is used to make tatami is called igusa, and there are several igusa-producing regions in Kyushu. It is here that a young man watched his father working diligently at igusa production, and grew up to have exceptional motivation and powers of pursuasion, breathing new energy into the local igusa industry. That young man is Soejima‘s Naoki Ishibashi. Let’s go with him on a journey into the world of igusa.

I don’t think many young people today are familiar with hanagoza made of igusa, to be honest.

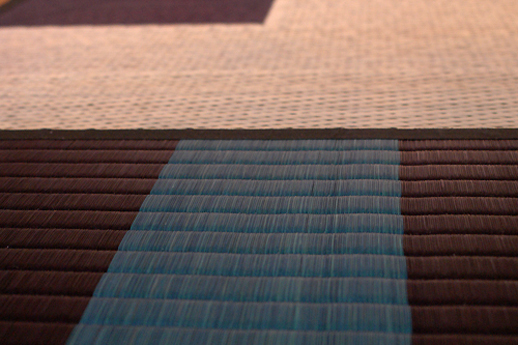

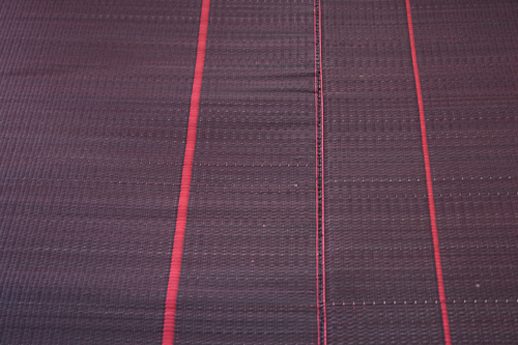

It could be that young people haven’t even heard the word “igusa” before. Igusa is a plant that is used to make tatami mats. That grassy smell when you walk into a tatami room – that’s the aroma of igusa. Patterned mats made with igusa are called hanagoza.

Has this area (Okawa City, Yanagikawa City, Oki-cho, in Fukuoka) always been an igusa producing region?

Yes, it has. Igusa is grown in paddy fields, and my father tells me that long ago this whole area was almost completely used for growing igusa. The seedlings are started in August, and they’re planted in the fields in December, and in April the tops of the plants are cut. Around here, scenes of people doing that kind of work were once an everyday sight. Back then, there were over 2000 hectares used for growing igusa. But now there are only around a hundred hectares in use.

Did it change because of the way people build their houses has changed?

That’s one reason. An even bigger reason is because these days 80% of the igusa used in Japan is produced in China. Within Japan, aside from right here, Hachiyo in Kumamoto prefecture is another igusa production area.

But as long as it’s cheap and the quality isn’t too bad, most people don’t care if what they buy is produced domestically or in China, do they?

Yes, but the quality is very different, so that’s a problem. (laughs) I wouldn’t mind if people could understand the difference in quality and price and base their choices on that, but price alone is no way to make a decision. There are durability issues with the China-grown product due to climate and cultivation techniques. Not only that, but it’s not clear how much or what kind of agricultural chemicals are being used, so it’s unknown what kind of affect on health there could be. In comparison, domestically-grown igusa is grown with a lot of personal care, and it’s durable and of high quality. In addition, it seems that the climate here in Japan is suited to growing igusa, and we are able to grow tough, resilient igusa here.

I see. In recent years, people have stopped building tatami mat rooms quite so much, but I think there are a lot of Japanese people who love that tatami room smell, so it might be necessary to raise awareness of igusa, don’t you think?

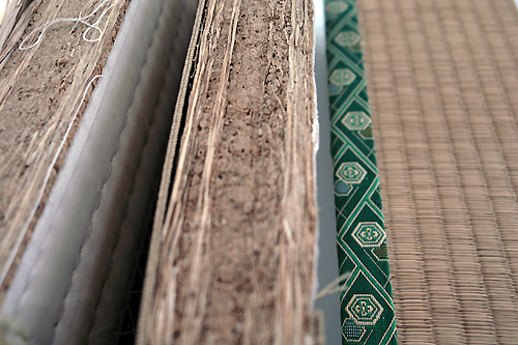

Yes. Even with tatami, the surface was originally covered with an igusa mat and the inside of the mat filled with rice straw. These days, over 90% of tatami mats are based on a core of stryrofoam or wooden boards. Even in a house that costs a hundred million yen to build, in most cases the tatami won’t be of the traditional variety.

Is that so? I had no idea. I had always believed that tatami was made of entirely natural materials.

Most people in the construction industry aren’t even aware of it. (laughs) Tatami made of igusa and rice straw is actually quite difficult to use. It’s hard to get hold of the materials, and difficult to make. On top of that, it’s very heavy, so industry people try to avoid using it as much as possible. When a designer or an architect writes “real tatami” on a plan, many people in the industry take that to mean, “if it’s got tatami on it, that’s good enough.” (laughs) You start to see a gap emerge between the designer and the builder there. Maybe not so much for apartments, but with houses, natural tatami has good breathability, and with maintenance the same set can be used for decades. The natural material breathes, which helps keep the house cool in summer and warm in winter. That’s why I like to recommend tatami that is made with rice straw and igusa.

You mentioned natural materials. Your JAPAN BRAND project, Kusawake, makes use of natural materials too, doesn’t it? Could you tell me how this project got started?

Igusa has been grown in this region for over four hundred years. We are the top producer of hanagoza in the country, which is woven patterned mats made with igusa. Even so, the industry continues to shrink, and I thought if it kept going at this rate we’d be in trouble. There is a growing sense of crisis in the industry. We got four production and distribution companies together to tackle the situation. We also had a designer come and participate, and started off by making some prototypes.

I see. You also invited a designer to participate. How did the collaboration go?

I’d say essentially it went very well. In our case, we have always put emphasis on the importance of thinking of the user first when developing new products. We emphasized that from the start, and I think that’s why it went well.

Speaking of distribution of igusa hanagoza, what kind of shops are you selling it to?

We sell wholesale to department stores, mail order, and home improvement stores. We sell the designer, value-added products at interior design shops. With the JAPAN BRAND project, we didn’t want to have to build a whole new distribution network over from scratch. We used what we had already built up from our regular work. We used our pre-existing sales channels as a base for our product development.

Tell me, how did you find a designer to collaborate with you?

Oh, you don’t just find someone. (laughs) Even if you ask a professional designer and they seem half-interested, it doesn’t go well. The designer has to understand the basic appeal of igusa and approach us himself. If we don’t do that, it ends with “I gave it a try and this is what I came up with,” and we never manage to get a marketable product out of it.

I love how you’re so young and yet you don’t rush things.

I have worked in restaurants and real estate, so I’ve got management experience. I know what I have to do to have a solid business and promote igusa.

I imagine you must be influenced by your father, who owns an igusa factory?

My father (Yoshiyuki Ishibashi, owner of Hanagoza, a hanagoza factory) is very serious about running his igusa factory, and he only wants to make good things. I always watched him at work when I was little, and I think part of him has definitely rubbed off on me. But actually, I never had any intention of working in an igusa company. (laughs) I don’t think my father expected it either. I had quit the company I worked at and I’d come back to my family’s home for a while, and the president of this company asked if I’d help out a bit. I started out with a very lighthearted feeling, but before I knew it, I was in deep.

You must have an attachment to the industry after all.

I think that’s true. I think what we need to do next, what is more important than collaborating with a designer or making novel plans, is to work to get average people to understand how great tatami is, and how great igusa is. Igusa has antibacterial and air purifying qualities, and after growing for only eight months, it can be harvested and used as home interior elements that last for years. It’s a really environmentally friendly product. In that sense, I think igusa is a really good match for the current age.

Soejima Isao Shoten Co., Ltd.

Nakakimuro 23-1, Okawa City, Fukuoka

A Word from a Regional Project Participant

Oki-cho Chamber of Commerce

JAPAN BRAND Development Assistance Program Officer

Recently there has been an increasing interest in Japanese-style interiors, both overseas and within Japan. Japanese living spaces have been gathering attention. Igusa products made in the Chikugo region are high-quality, high-end goods compared to grass products made in China. In particular, igusa grown in the Chikugo area has a densely porous quality. Because of this, it has the ability to absorb harmful substances in the air such as formaldehyde and nitrogen oxide, making it a very environmentally friendly, safe, healthy product. In this sense, it is a product that matches the needs of consumers today. We started the JAPAN BRAND Development Assistance Program in FY2007 and we’re mainly working on developing a brand for hanagoza products. Growers, processing companies, and distribution people have all gotten together to make a strong, popular product line. Our goal for 2008 was to produce results in the domestic market, and our goal for 2009 is to establish a flagship brand. The local industry people are guiding us in creating our brand. There are six participating companies: Soejima Isao Shoten Co., Ltd, Shinwa Sangyo, Fukumoto Shoten, Toshin, Sun Eight, and Ikehiko Corporation. In addition, we have had some collaborative assistance from Kyushu University Graduate School of Design. Now, we’re going to work on raising awareness of the health and environmental benefits of igusa, targeting women in their 20s and 30s who have a preference for the LOHAS style, and continue to develop strong, popular products.

Japan Brand

Japan Brand