Young Weavers Changing Kurume Kasuri: Nomura Orimono

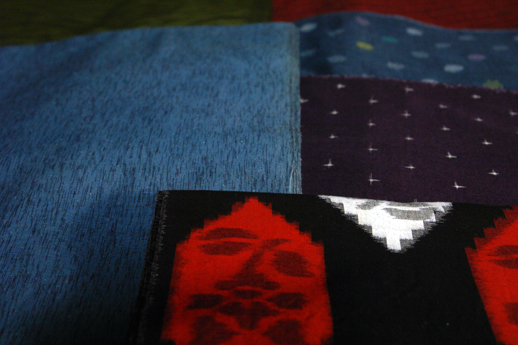

While many people outside Japan may not know the name Kurume Kasuri, the look of the cloth itself will probably ring some bells. Kasuri weaving is named for the distinctive ikat pattern it produces. Aside from Kurume, Iyo Kasuri and Bingo Kasuri are also well known within Japan. While this fabric is very traditional, it’s not very popular with younger people. This is where the new generation of textile manufacturers in Kurume have begun to rise to the challenge of innovating with their products to reach new audiences. They’ve been creating a buzz about their craft, and are beginning to set their sights overseas. This week we spoke to the fourth generation owner of Kurume Kasuri textile producer Nomura Orimono, Shutaro Nomura.

Interviewed by Takafumi Suzuki. Translated by Claire Tanaka.

Mr. Nomura, did you start working at this studio as soon as you graduated from school?

No. At first, I worked as a salesman for a certain Japanese auto maker. When I was a child, I loved cars. But personally, I didn’t want to work for someone else forever. I always wanted to run a business someday. That thought was always with me.

You had something of an entrepreneurial spirit…

Yes. I left home at fifteen and went to high school at a boarding school in Mie prefecture. I think that helped me to develop a very independent spirit. Even so, I never thought I’d be the one to take over the Kurume Kasuri workshop until my grandfather told me so. I’m the second son after all…

Your older brother isn’t working in the family business?

My brother chose to become a public servant, so I had a strong sense of having to protect the family business. Also, I had ambitions of being an entrepreneur. My grandfather noticed that about me. So he said to me, “You’ll be the one to take over the business.”

I think a lot of people would just say “No!” if they were asked to take over their family’s traditional business. How did you feel?

At that time I’d been living in Tokyo and I had a pretty good life. I was a little reluctant to throw all that away and return to my hometown, but I had no reservations about taking over the family business. I think that’s because I had spent time at the workshop since I was a child, and it was a very natural place for me to be.

Did you ever help out in the shop when you were a kid?

Yes. I was always in and out of the workshop, and helping out was one of my favorite things to do when I was a kid. I loved riding with my dad in the car making deliveries. I think I liked spending time with adults. I like people.

OK, Mr. Nomura, could you tell me a bit about the appeal of Kurume Kasuri?

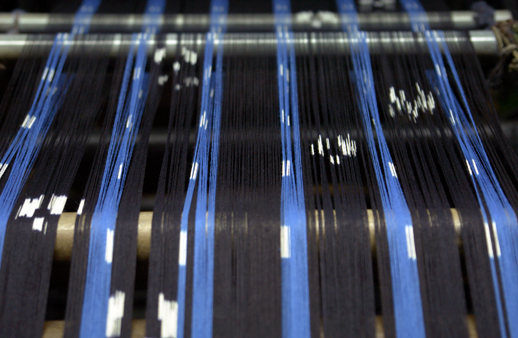

The beauty of the delicate, calculated weave and the texture of the natural cotton material are the two major points. In addition, I think that the high level of skill that our artisans put into their work also adds a certain appeal to the products.

When you say “high level of skill,” what kind of skills are you talking about exactly?

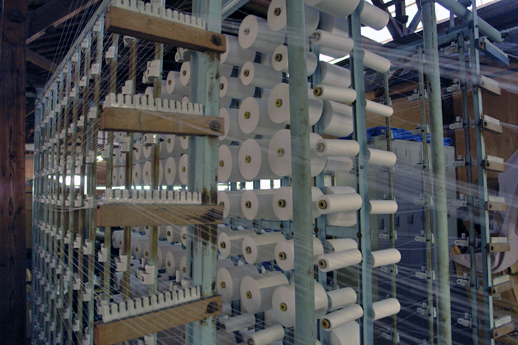

The most difficult thing to do is to get the pattern on the warp and the pattern on the weft to match up. Kurume Kasuri requires a lot of patience. One bolt (40cm x 12 meters) takes about two months to complete. There are thirty different steps involved. A simple explanation of the steps involved would be that we take the white threads and tie them with yarn, dye them with indigo, and then weave them. After that, we wash the cloth in water, dry it, and then shape it.

It must be hard to convey the level of skill required when you’re out in the marketplace.

It is. Kurume Kasuri has a lot of longtime fans. Once they experience the comfort of a kimono made of natural materials, it feels so good that many people come back as repeat customers. But talking isn’t enough to get young people to understand. You’ve got to give them a gut reaction, of “that’s cool” or “that’s cute.” Speaking personally, when I buy clothing I always go with my gut reaction, so I can understand why that’s important.

It seems that you’ve been gradually getting better at sniffing out good design with your JAPAN BRAND project.

Yes, that’s right. This is our third year working with the project. During the first year, we had all these pipe dreams and we just couldn’t narrow down what we really wanted to do. Plus, we had a very low level of awareness. Over the years, participating companies got thinned out through a process of natural selection until we were left with just the companies who were serious about making a new kind of kurume kasuri. Our bonds naturally got stronger, and we developed a common direction.

So the number of participating companies in your JAPAN BRAND project changed?

At first there were thirteen participating companies, but now there are only four. The ones left are all companies headed by people in their twenties and thirties. You could say the people who are open to new things and new designs are the ones that have stuck it out. But, the things that we textile manufacturers want to sell are bolts of cloth, plain and simple. So I think that by connecting with people who have a certain sense about these things enabled us to improve our designs.

Could you give me an example of connections that have helped you?

For example, there’s a shop in Yokohama called Rourou and one in Harajuku’s La Foret shopping complex called Ninita where people are actually selling clothes, planning clothing lines, and designing things. The way they stand on the sales floor listening to the real voices of clients is something us textile manufacturers can never do. They have access to the fresh ideas that people in the market want, while people like us on the manufacturing end could never come up with those ideas on our own. That is how we’ve been able to make our products more and more cosmopolitan over the years. We met those retail-based people at trade shows, for the most part. I think those relationships are very important. Without those people, we would have never amounted to anything more than a big fish in a very little pond.

Now finally, tell me your vision for the coming years.

I want Kurume Kasuri to become recognized as a cloth that can be made not just into kimono, but into western-style clothing as well. In order to do that, I’ve got to keep meeting people with good aesthetic sense, and keep trying new things with cloth. And more than ever, I’d like to make Kurume Kasuri known to the entire world.

A Word from a Regional Project Participant

Kazunari Mizuki

Kurume Kasuri is a traditional craft with more than two hundred years of history. Shinpu Kurume Kasuri is the name of our project which is meant to act as the natural successor to this traditional craft, shining new light on it and bring brand recognition to the craft. The name of the product, “Shinpu,” which means both “new wind” and “new style” was chosen to represent the young successors and the new wind that they bring to the business, causing it to fly out into the world. We have come to believe that just making a good product is not enough to succeed in this day and age. We’ve got to maintain tradition while also incorporating modern elements. The number of local participating companies has been dropping every year, but in reality, the density of the project has gotten thicker and the collective consciousness has increased. The remaining four companies are all headed by young people, which we consider a very lucky thing. Their youth gives them the ability to absorb new things easily, and they take a bold approach, even when setting their sights overseas. The encounters with people at commercial exhibitions have been a tremendously inspiring experience. Kurume Kasuri itself came from one young woman’s inspiration over two hundred years ago. Many people over the years have been loyal users of the cloth. We’re hoping that our young entrepreneurs can take this traditional craft and make it into something with added value, something with design and style that can match the modern age and take flight, bringing Kurume Kasuri to the world. We know that creating a brand doesn’t happen overnight. We’ve got to keep our goals in mind at all times and work diligently if we want to succeed. Even here at the Chamber of Commerce, we are ready and willing to put in the steady effort required to help our region’s traditional craft, the entire Kurume Kasuri industry, to get airborne.

Japan Brand

Japan Brand