Gem Town Father and Son: Kiseki Chokoku Ohyori

Kofu, in Yamanashi prefecture, is a gem town. It all started in the Edo period when quarts crystals were discovered in the mountains there. However, these days many people no longer associate Kofu with gems. In order to confront this situation, the jewelers of Kofu are participating in the Japan Brand project with something called the Koo Fu Project. Out of a great number of jewelry manufacturers we heard from a small gem engraving workshop run by a father and son, called Ohyori. Speaking to these men, we really got a feeling of the sense of possibility that Kofu holds. The true gems in this town are the craftspeople themselves.

Q: There certainly are a lot of people in the gem industry here in Kofu.

A: Oyori Yoshiro (father): Yes. This area has been a source for natural quartz crystals for a long time. That might have something to do with it. There are forty companies just counting the ones who belong to the sculptor’s guild alone. No one can really say how many companies there are all together. One might say a thousand, another would say 1500.

Q: Either way, that’s quite a number. But, that just goes to show how much work there is in the gem industry here, doesn’t it?

A: Oyori (father): If you talk to the old timers around here, they’ll tell you how it was in the 1950s and 60s, how they couldn’t produce enough to keep up with all the orders. They always say, “Those were the good old days.”

Q: So you’re saying it’s not quite as booming as it used to be?

A: Oyori (father): That’s right. “Good” is not a term I would use to describe how it is now. Even so, there are still so many people living in Kofu with valuable technical skills relating to gemstones, and that makes this a very special place. Gems may seem simple but a number of expert technicians have to work together: grinding and polishing stones, processing precious metals, setting stones, and so on, before a single piece of good jewelry can be made. In that sense, Kofu still has a lot of latent potential. But even if an old guy like me comes up with an idea, nothing good will come of it. (laughs)

Q: But there’s already a successor in your workshop, isn’t there? Tomohiko, you’re the eldest son. Tomohiko, had you always intended to take over the family business from your father?

A: Oyori Tomohiko (son): Yes, ever since I was very small I had a vague idea that I would take it over. Lucky for me I’m fond of making things with my hands. That’s why I had no hesitation in choosing to study design in high school before entering a trade school to learn the basic jewelry-making techniques. I started working at my father’s workshop directly after I finished my studies at gem school. There were no major conflicts; it was a natural flow of events and it still is now.

Q: Now, judging from what you’ve been saying, I imagine that it must be the young Tomohiko who is participating in the Japan Brand project, is that so?

A: Oyori (son): Yes, you’re right. In fact, we’ve been participating since the first year, and in that first year I participated as an advisor. As an advisor, I was responsible for teaching designers the basics of gemology. Most of the designers who came together for the Japan Brand project had no knowledge of how to process stones. So I taught those people what is possible and what isn’t possible.

Q: How do designers wind up participating in the local Japan Brand project?

A: Oyori (son): Basically, I think the Kofu Chamber of Commerce and Industry sends out a call for applications to about two hundred design firms. On the first year we had fifteen, and on the second year nineteen people came. I myself participated as not an advisor, but as a designer in the second year. Normally, I’m working as an artisan while at the same time I’m teaching about gems at the trade school. I really want to create opportunities for young people. In order to do that I decided it was important for me to try and design a new product by myself. My young students are coming of age in a difficult time, and they’re all very serious about their work.

Q: I understand the local Japan Brand project unveils a new collection every year. What kind of process do you go through to decide which designs to use for the collection?

A: Actually, with the Koo Fu Project, we invite a certain very well-known person to come as a design advisor: Naoto Fukasawa. Mr. Fukasawa is an industrial designer who is originally from Yamanashi, and while he’s very busy, he generously makes the time to hold workshops for our project. He held seven workshops last year, and five this year, so he’s held twelve so far. The great thing about Mr. Fukasawa is that he really puts a lot of energy into our project. He doesn’t look at the list of participants, he just looks at the faces of the participating designers, and the works they have made. It’s all there in his head. As his student, I have a lot of respect for Mr. Fukasawa as a designer.

Q: Tell me, Tomohiko, what kind of pieces have you designed?

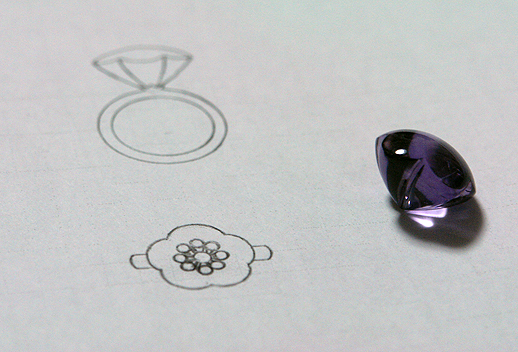

A: Last year, I made a design with a cut quartz crystal enveloped by another quartz. After I began participating as an official designer, I made a design based on a cherry blossom motif. Although I whipped it up over quite a short period of time, I personally think it’s very good. I was really happy when Mr. Fukasawa praised my work.

Q: How did you feel when you designed something new?

A: It reaffirmed for me how many helpful people there are around Yamanashi. Even when I made this piece, in order to get the raw metal I had to call in a favor from an old friend from my school days who works in precious metal processing now. As my father was saying, although the jewelry industry is big here, there are a lot of different companies. Places that make their own original products, places that only fill orders, places with nearly a hundred employees, places with products that target young people, places which target the middle to old age bracket, and on and on. Everyone has their own way of doing business, but it is very reassuring to have so many of the same industry in one place. I think it is a real strength of the land in Kofu. That really struck me.

Q: I imagine there aren’t many places like Kofu, not just in Japan, but in the world, with so many jewelry manufacturers gathered in one place.

A: Ohyori (father): Yes, that’s right. That’s why in the old days, we did a lot of exporting, and this region was comparatively well-known, mostly in other Asian countries but also all over the world. When foreigners read “kofu” they tend to pronounce it as “koo-fu.” Actually, that’s where our Japan Brand project got its name. I think if the young guys here like my son can participate in this project and inject some new ideas into the region, I’ll be really happy.

Q: As a senior craftsman, what do you feel is necessary to get new blood circulating?

A: Oyori (father): I suppose, meeting people? If you’re just sitting holed-up in the workshop toiling away, your world won’t expand for you. When I was younger, we had a technician’s association where people from different companies with the same trade would get together and we’d ask arts-related teachers to come, or invite more experienced artisans to come, and we studied really hard. So in that sense, my son is meeting people through projects like JAPAN BRAND that he wouldn’t have otherwise had a chance to work with, making connections, and I think that’s a good thing. The founder of this workshop, my father, he was a classic craftsman, and he was always very silent and still when he worked.

Q: Finally, Tomohiko, as representative of the younger side, tell me what vision you’ve got for the future, if you’ve got one.

A :Oyori (son): This might sound like a dull goal, but more than anything, I want to be able to do my work well, so that I can finish each piece without any imperfections. (laughs) And then, I’d like to eventually get into manufacture and sales, selling through the internet and having a store where I can sell my original designs directly to customers. I think that would be really fun.

Kiseki Chokoku Ohyori Marunouchi 3-25-1, Kofu City, Yamanashi

A Word from a Regional Project Participant

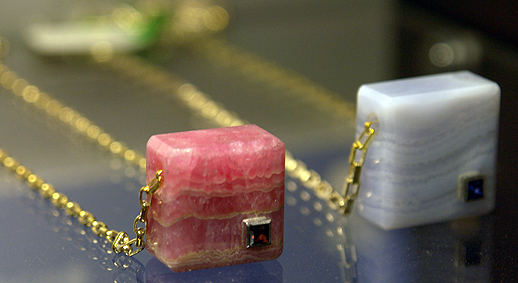

The Koo Fu Project was established in 2005 (how many years has it been now?) by members of the Yamanashi jewelry industry out of fear about the current industry situation. The project became a Japan Brand project in 2007. Kofu City, Yamanashi has been a jeweler’s town since long ago. One third of Japan’s jewelry is produced here, making it the largest production area in the country. The local traditions are still alive here, and we have many skilled craftspeople and superior materials. However, many people still don’t associate Kofu with jewelry. I think this was partly because most of the work people have been doing is making OEM products for big apparel manufacturers and working behind the scenes for famous brands. The original goal of the Koo Fu Project was to gain some name recognition with consumers. If we could get a great number of people to start thinking, “I want to buy jewelry from Kofu!” then I’d be a happy man. The core of this project is the use of materials that are unobtainable outside of Kofu, namely new metals. One of those is a type of platinum with a very high degree of purity, which is very hard and difficult to damage, called “Koo-fu Pt950.” Another is “Koo-fu K18WG,” a specially developed white gold which is not plated and contains no nickel. We used these new materials and held workshops where young jewelry designers worked on ideas for new designs, and released the results as the “Koo Fu Collection,” in order to improve our name recognition. We are hoping that can become one way in for us. Of course we also have our eyes set overseas. The people of the world generally have the image that “Well-designed jewelry is made in Europe.” I think if people from other countries take our Kofu jewelry in their hands and see the truly high level of quality we’ve achieved, we’ll be able to break that preconception.

Japan Brand

Japan Brand